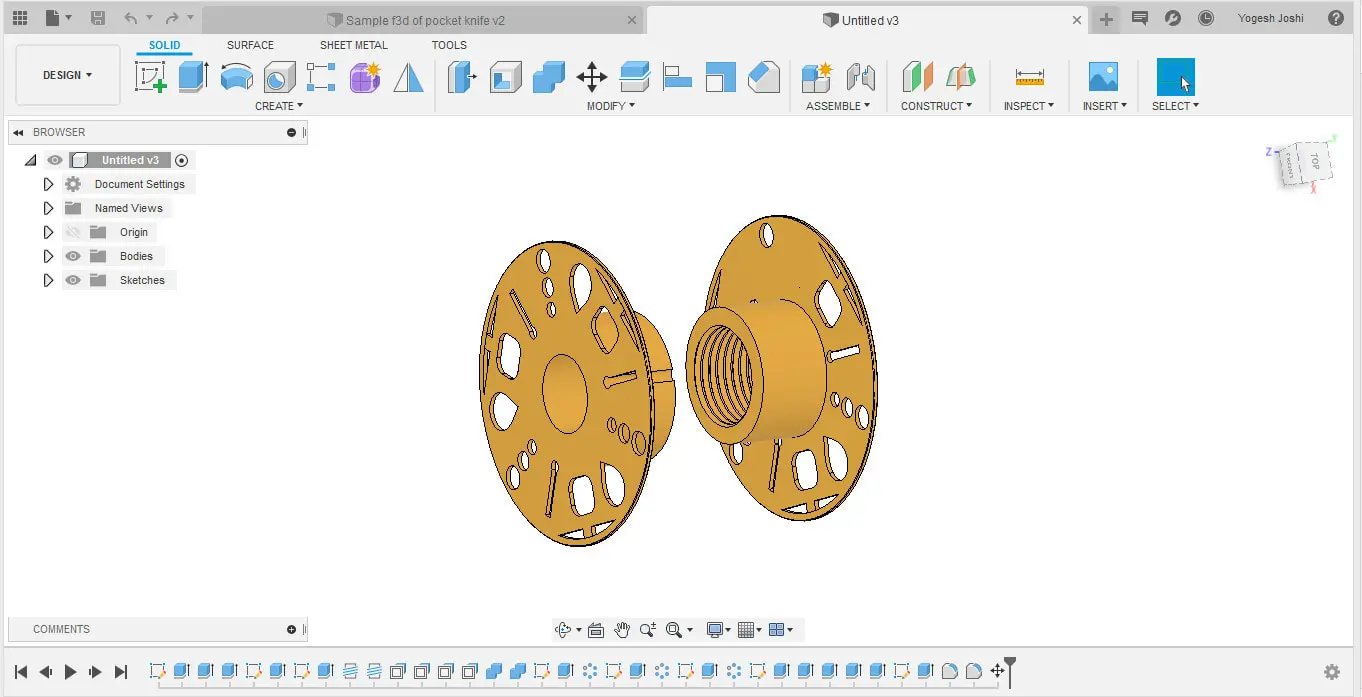

3D print design, molding, and CAD design in Fusion 360 constitute a comprehensive and versatile approach to product development and manufacturing. Fusion 360, a powerful software tool, seamlessly integrates these three essential processes. Starting with 3D print design, designers can conceptualize intricate and precise models, optimizing geometries for additive manufacturing. The molding capabilities enable the transformation of these digital designs into physical objects through various molding techniques, ensuring mass production feasibility.

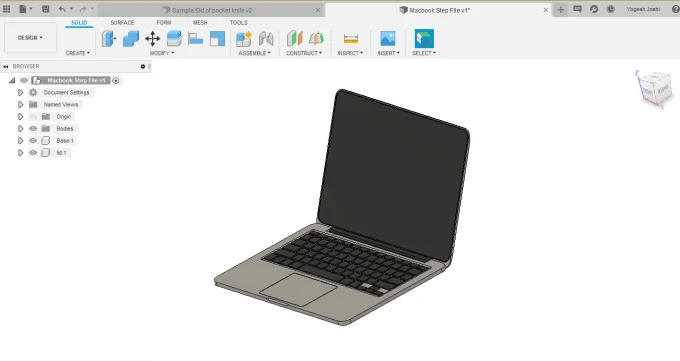

Throughout this entire journey, Fusion 360’s CAD design functionality underpins the process, allowing for precise modeling, simulation, and analysis, ensuring the viability and integrity of the designs before they proceed to the manufacturing stage. This integration of 3D print design, molding, and CAD design in Fusion 360 streamlines the product development process, from ideation to realization, fostering innovation and efficiency in the modern manufacturing landscape.

Table of Contents

What are the uses of Fusion 360?

Fusion 360 is a versatile and comprehensive software platform that serves various purposes across design, engineering, and manufacturing disciplines. Some of its primary uses include:

- 3D CAD Modeling: Fusion 360 is widely used for creating detailed 3D models of products and components. Its parametric modeling capabilities allow for precise design and easy iteration.

- Industrial Design: Designers use Fusion 360 to develop aesthetically pleasing and functional products by combining engineering and artistic design elements.

- Mechanical Engineering: Fusion 360 enables engineers to simulate mechanical systems, perform stress analysis, and evaluate how components will interact under different conditions.

- Prototyping: The software aids in rapid prototyping by creating virtual prototypes, reducing the need for physical iterations and saving time and resources.

- 3D Printing: Fusion 360 facilitates the design of models optimized for 3D printing, including the ability to generate support structures and configure print settings.

- CAM (Computer-Aided Manufacturing): The integrated CAM capabilities in Fusion 360 allow users to generate toolpaths for CNC machining, turning designs into physical objects.

- Simulation and Analysis: Engineers can simulate real-world conditions to test how their designs will perform under various scenarios, ensuring their functionality and reliability.

- Sheet Metal Design: Fusion 360 offers tools for designing sheet metal components and generating flat patterns for manufacturing.

- Electronics Design: While not as comprehensive as dedicated electronics design software, Fusion 360 can help integrate electronic components into mechanical designs.

- Collaboration: Fusion 360’s cloud-based platform facilitates collaboration among team members, enabling real-time sharing and reviewing of designs.

- Rendering and Visualization: Users can create photorealistic renderings of their designs, helping to communicate ideas and concepts effectively.

- CAD/CAM for 2D Machining: Fusion 360 supports 2D machining workflows, making it suitable for tasks like laser cutting, waterjet cutting, and simple milling operations.

- Product Lifecycle Management (PLM): Fusion 360 can be used as a lightweight PLM tool, allowing teams to manage versions, revisions, and project-related data.

- Education and Learning: Fusion 360 is often used in educational settings to teach design, engineering, and manufacturing concepts to students.

- Startups and Small Businesses: Fusion 360’s affordability and versatility make it a popular choice for startups and small businesses looking for a comprehensive design and manufacturing solution.

These are just some of the many applications of Fusion 360. Its integrated nature and wide range of features make it suitable for various industries and stages of the product development lifecycle.

Also, Read: Best Practices for Instruction Manual Design

Best Practices for 3D print design, molding, CAD design in Fusion 360

Certainly, here are some best practices for 3D print design, molding, and CAD design in Fusion 360:

3D Print Design:

- Optimize for Additive Manufacturing: Design with the capabilities and limitations of 3D printing in mind. Utilize support structures effectively and design for minimal overhangs, bridges, and other challenging geometries.

- Proper Scaling: Ensure accurate scaling of your model before printing. Double-check units and dimensions to prevent errors.

- Wall Thickness: Maintain appropriate wall thickness to ensure structural integrity and prevent issues like warping or fragile parts.

- Orientation: Choose the optimal orientation for printing. Consider factors like support material usage, surface finish, and print time.

- File Format: Save your 3D print design in a suitable file format like STL or OBJ that’s compatible with your 3D printer.

Molding:

- Draft Angles: Incorporate draft angles in your design to facilitate easy ejection of the molded part from the mold.

- Uniform Wall Thickness: Similar to 3D print design, maintain consistent wall thickness to ensure proper flow and cooling during the molding process.

- Rounded Corners: Rounded edges and corners can prevent stress concentrations and improve the mold’s longevity.

- Gate Placement: Strategically position gates to allow even distribution of material and minimize defects like air traps or sink marks.

- Material Selection: Choose appropriate materials that match the requirements of the molding process and the final product’s properties.

CAD Design in Fusion 360:

- Organized Design Hierarchy: Create a structured design hierarchy using components and assemblies. This makes it easier to manage complex designs.

- Parametric Design: Utilize parametric modeling to establish relationships between different parts of your design. This enables quick design changes and updates.

- Iterative Design: Plan for iterations and updates by keeping your design modular and easy to modify.

- Version Control: Maintain version control to keep track of design changes and collaborate effectively with team members.

- Simulation and Analysis: Leverage Fusion 360’s simulation capabilities to test your design’s performance under different conditions, ensuring its integrity before manufacturing.

- Regular Backups: Regularly save and backup your CAD files to prevent data loss due to software crashes or other issues.

Remember, these best practices can vary based on the specific project, manufacturing process, and requirements. Continuous learning and adaptation are essential to staying up-to-date with evolving technologies and design methodologies.

What we offer:

Expert 3D Print Design, Molding, and CAD Design with Fusion 360

At “The Technical Drawing Company“, we bring your ideas to life with precision and innovation using the power of Fusion 360 software. With a team of skilled designers and engineers who are experts in Fusion 360, we offer a comprehensive suite of services that span 3D print design, molding, and CAD design. Our goal is to be your trusted partner in turning concepts into reality, providing cutting-edge solutions for diverse industries.

Our Services:

- 3D Print Design: Our adept designers specialize in crafting intricate 3D print designs that are optimized for additive manufacturing. We leverage Fusion 360’s capabilities to create geometrically complex models that maximize the potential of 3D printing technologies. From concept to final design, we ensure that every element is meticulously considered for successful and efficient 3D printing.

- Molding: With our expertise in Fusion 360, we seamlessly transition digital designs into physical objects through molding. We incorporate essential mold design principles, including draft angles, proper wall thickness, and gate placement, to ensure smooth manufacturing processes. Our team ensures that each design aligns with the requirements of the chosen molding technique, enhancing efficiency and minimizing defects.

- CAD Design: Our CAD design services using Fusion 360 encompass the entire product development cycle. We create parametric models that allow for flexible design iterations, ensuring that your vision evolves with precision. Our designs are rooted in engineering excellence, taking into account structural integrity, mechanical performance, and manufacturability.

Why Choose The Technical Drawing Company?

- Fusion 360 Mastery: Our team consists of Fusion 360 experts who are well-versed in utilizing the software’s full spectrum of features to meet your design and manufacturing needs.

- Custom Solutions: We understand that every project is unique. Our tailored approach means that you receive solutions that align perfectly with your goals, whether it’s a complex 3D print design or a molding process optimization.

- Collaboration: We value your input and insights. Our collaborative approach ensures that your vision is at the forefront of our design process, resulting in outcomes that exceed expectations.

- Innovation and Efficiency: By leveraging Fusion 360’s cutting-edge tools, we streamline design processes, reduce iteration cycles, and bring your products to market faster.

- Quality Assurance: Our commitment to quality is unwavering. Rigorous design analysis, simulations, and testing are integral parts of our process, ensuring the reliability and performance of your designs.

- End-to-End Support: From concept to production, we provide comprehensive support throughout the entire lifecycle of your project. Our team is dedicated to guiding you at every step.

When you partner with “The Technical Drawing Company”, you’re collaborating with a team that not only understands Fusion 360 but also shares your passion for innovation. Our track record of successful projects across various industries is a testament to our expertise and commitment. Contact us today to embark on a journey of unparalleled design excellence and manufacturing precision.

Looking for 3D Print design, Molding, CAD Design using Fusion 360?

Request for a Custom Quote (free, no-obligation)

- Submit your custom requirements and get the price quote with the delivery timeline.

Submit your requirements below