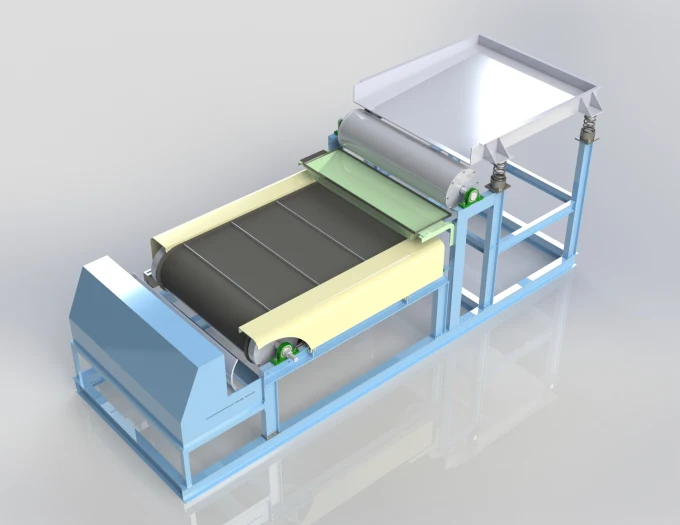

How to do 3D Modeling and 2D Drawings using Solidworks? Elevate your manufacturing processes with our expertly crafted 3D models in SolidWorks. From precision manufacturing to 3D printing, laser cutting, CNC machining, and plastic injection molding, our designs are optimized for each process. Experience seamless integration, precision, and efficiency in every project. Creating 3D models and 2D drawings using SolidWorks involves several steps.

Table of Contents

3D Modeling and 2D Drawings using Solidworks

Here’s a general guide to help you get started:

Creating 3D Models

Sketching

Start by creating 2D sketches of your design using various sketch tools like lines, arcs, circles, etc. These sketches will form the basis of your 3D model.

Extruding and Revolving

Use the “Extrude” command to give thickness to your 2D sketches and convert them into 3D features. Similarly, the “Revolve” command can be used to create rotational features.

Adding Features

Use features like fillets, chamfers, holes, cuts, and more to refine and add complexity to your 3D model.

Assembly

If your design involves multiple parts, you can create an assembly by bringing these parts together. Use tools to define relationships between parts, such as mates and constraints.

Applying Materials and Appearances

SolidWorks allows you to apply different materials and appearances to your model to make it more realistic in appearance.

Rendering

You can render your 3D model to create high-quality images with realistic lighting and textures.

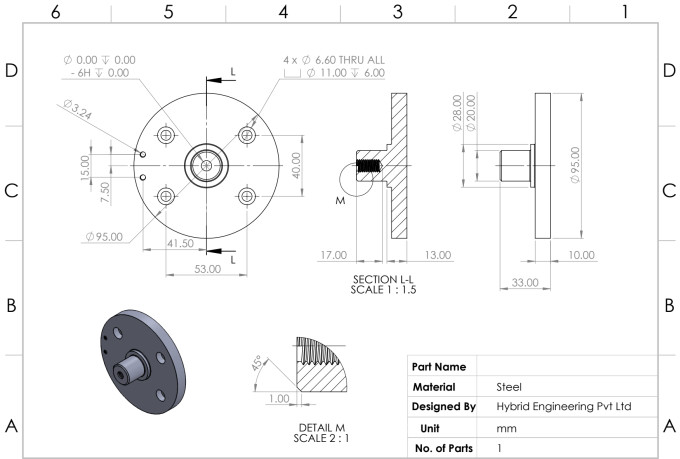

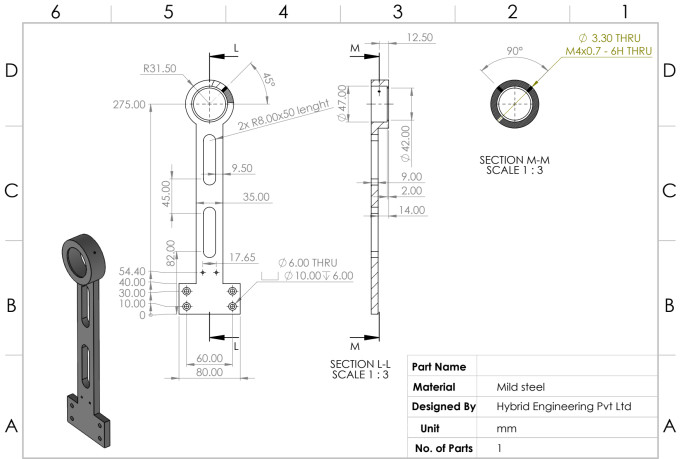

Creating 2D Drawings

Create New Drawing

In SolidWorks, start a new drawing file based on a template that suits your needs.

Insert Views

Insert views of your 3D model into the drawing. You can create multiple orthographic, isometric, and detailed views.

Annotations

Add dimensions, notes, and other annotations to the views. Use the “Smart Dimension” tool to create accurate dimensions.

Bill of Materials (BOM)

If your drawing involves an assembly, you can create a BOM to list the parts and quantities.

Detail Views and Sections

Add detail views or section views to highlight specific areas of interest.

Title Block

Add a title block containing information like part name, date, scale, etc.

Export and Print

Once your drawing is complete, you can export it to various formats or print it directly.

Remember that SolidWorks has a wide range of features and tools, so the specific steps you take might vary depending on your project. It’s recommended to go through tutorials, and guides, and possibly take a SolidWorks training course to become more proficient in using the software effectively.

SolidWorks also has an extensive help system and community resources where you can find detailed instructions and answers to specific questions you might have during the modeling and drawing process.

Also, Read: 3D Print Design, Molding, CAD Design in Fusion 360

How we can help you?

The Technical Drawing Company is your trusted partner for high-quality 3D modeling solutions tailored to meet your manufacturing needs. Our team of skilled engineers and designers specializes in using SolidWorks, a leading CAD software, to craft precise and efficient 3D models suitable for a range of applications, including manufacturing, 3D printing, laser cutting, CNC machining, and plastic injection molding.

Our Services

- Manufacturing-Ready 3D Models: We create detailed 3D models optimized for manufacturing processes. Whether you require parts for machinery, tools, or consumer products, our models are designed to ensure seamless integration into your production line.

- 3D Printing Design: Leveraging SolidWorks’ capabilities, we develop intricate 3D models perfect for 3D printing. Our designs account for material considerations, layer resolutions, and structural integrity, resulting in exceptional printed outcomes.

- Laser Cutting Designs: Our team crafts precise 3D models compatible with laser cutting systems. We optimize designs for smooth cutting, minimizing waste and ensuring accuracy in each cut piece.

- CNC Machining-Ready Models: If CNC machining is part of your production process, our experts create 3D models that translate seamlessly into CNC programs. This ensures a streamlined manufacturing process and reduces setup time.

- Plastic Injection Mold Modeling: For plastic injection molding, our specialized 3D models are engineered to account for factors such as material flow, cooling, and mold ejection. This results in molds that produce consistent and high-quality plastic parts.

Explore our comprehensive array of services tailored to meet your diverse design and manufacturing needs:

- Design / Modeling: With over 11 years of mechanical design experience, we specialize in creating impeccable 3D models and designs.

- 3D Files: From any CAD format to STEP and eDrawings, we offer precise 3D part and assembly files.

- 2D Files / Drafting: We provide 2D files in formats like AutoCAD, .DXF, and .DWG for your drafting requirements.

- 2D to 3D Conversion: Transform 2D drawings or images into sophisticated 3D models, breathing life into your concepts.

- Manufacturing and Prototyping: Whether for production or prototyping, our designs are optimized for both manufacturing and functional testing.

- Manufacturing Drawings: Accurate and comprehensive manufacturing drawings that streamline your production process.

- Manufacturing Design Consultation: Leverage our expertise for valuable insights in designing efficient manufacturing processes.

- Rendered Images: Visualize your final product with stunning rendered images that capture the essence of your design.

Output files: All CAD Formats Possible as per your requirement.

Partner with us for a seamless journey from concept to reality. Your vision, our expertise – a winning combination.

Why Choose Us

- Expertise: Our team consists of experienced engineers and designers proficient in SolidWorks and manufacturing processes.

- Precision: We pay meticulous attention to detail, ensuring that our 3D models align perfectly with your manufacturing requirements.

- Customization: Every project is unique, and we tailor our 3D modeling services to meet your specific needs and preferences.

- Collaboration: We believe in clear communication and collaboration. Your feedback is integral to our process, ensuring the final model meets your expectations.

- Timely Delivery: We understand the importance of project timelines. Our efficient workflow allows us to deliver high-quality 3D models within your desired timeframe.

Unlock the full potential of your manufacturing endeavors with our top-notch 3D modeling services. Contact us today to discuss your project and discover how we can transform your ideas into reality.